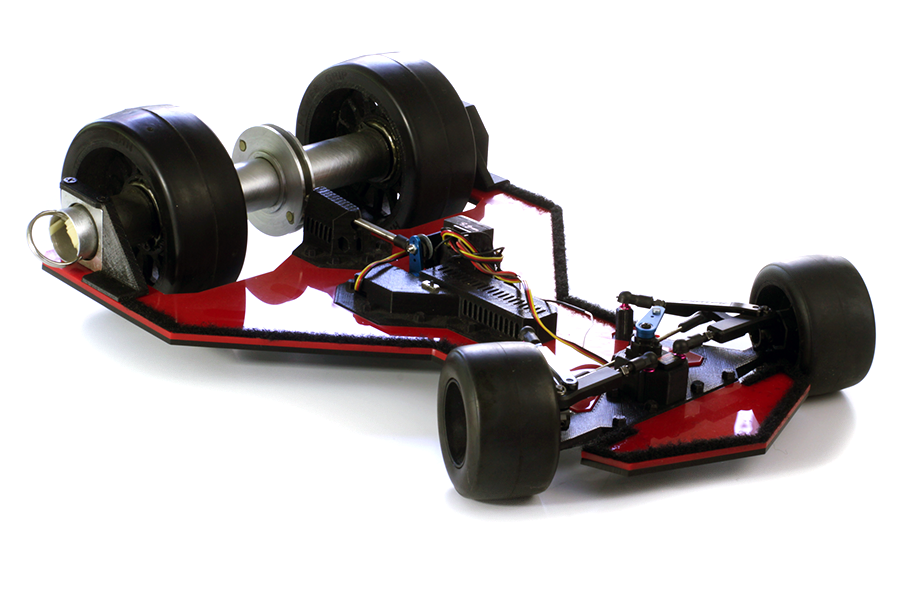

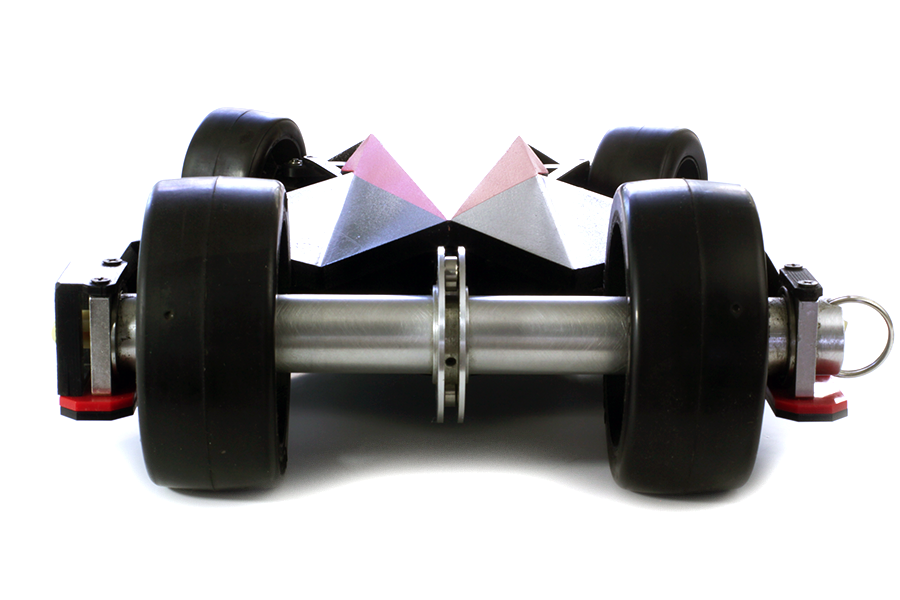

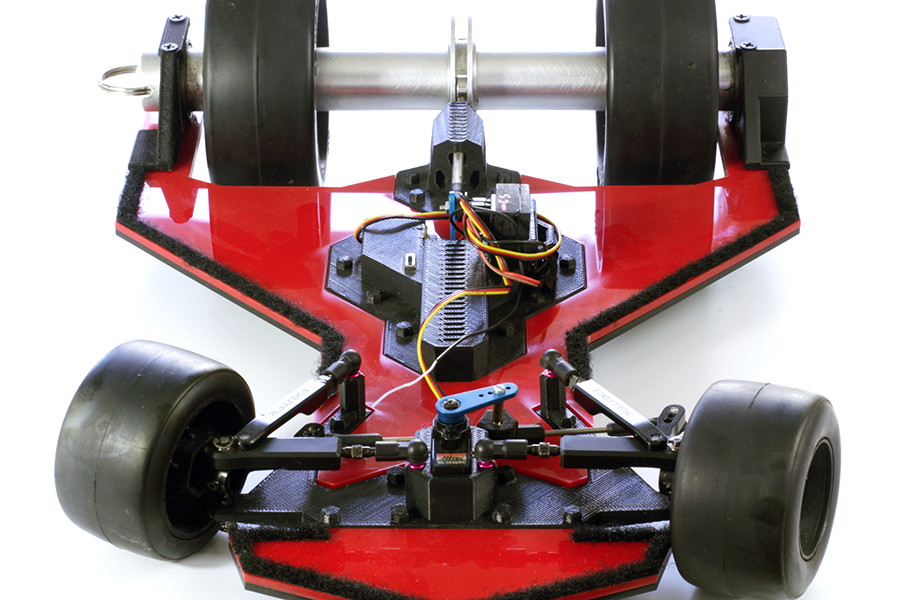

Andross is an RC car powered by a 16-foot rubberband and two servos. Engineered for performance from the ground up, Andross features suspension steering, custom 3D printed servo housings, and a lathed aluminum drive mechanism.

Andross was built to compete in Art Center College of Design's annual Formula E event. Formula E brings together over 20 international schools and professional organizations to design and build a rubberband powered RC car in 14 weeks.

|| Overview

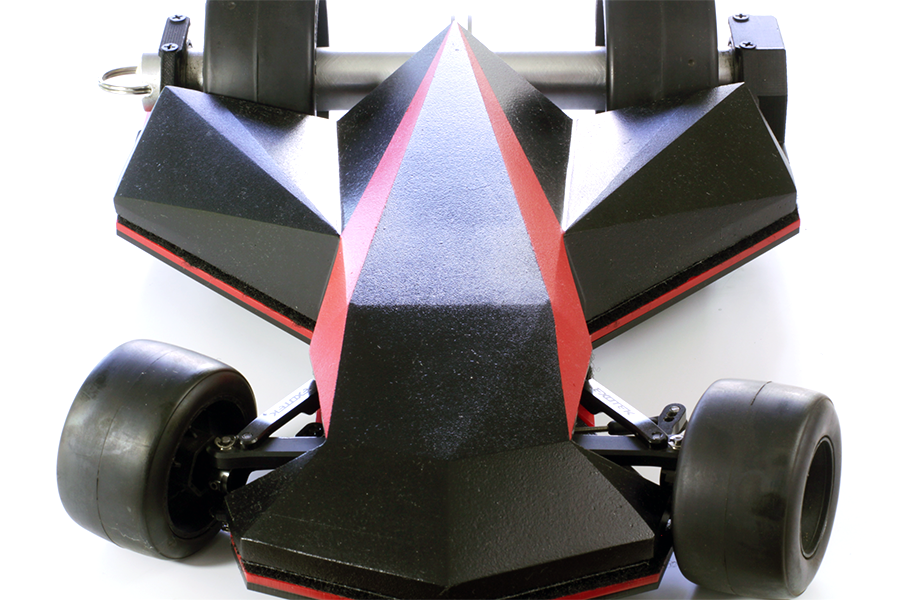

Andross was a 14 week group project culminating in the Formula E event and race. Our approach with Andross was to design a retro sci-fi inspired vehicle with a combination of modern manufacturing and rapid prototyping processes. The goal was to build a durable car that made up for what it lacked in speed with grip and turning ability, and had an attractive overall aesthetic that complemented the inner-workings of the vehicle.

|| Formula E Challenge

The annual Formula E race provides corporate and student teams with valuable experience in product development, engineering, team building and fabrication. All the while pushing their ability to find solutions under pressure, recover from failure, and ultimately win.

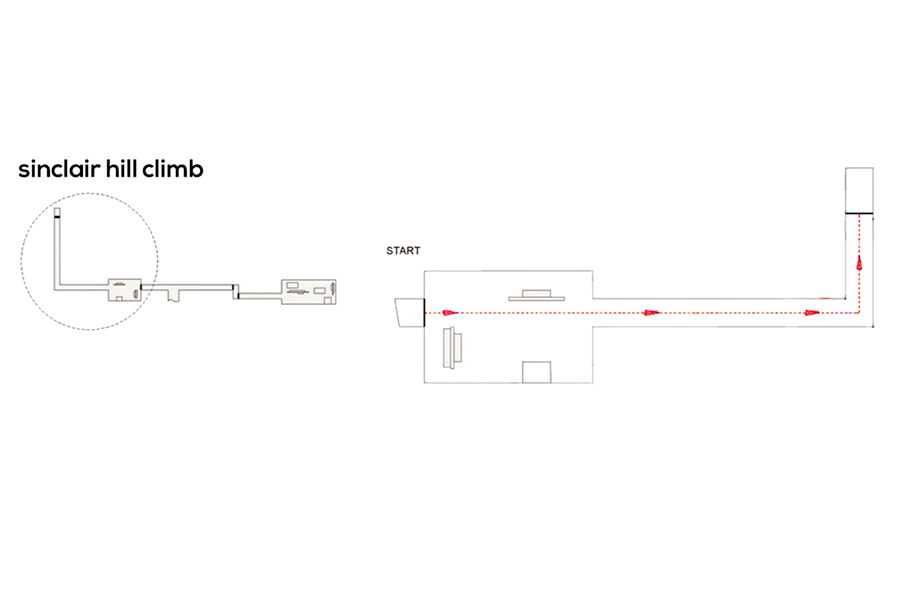

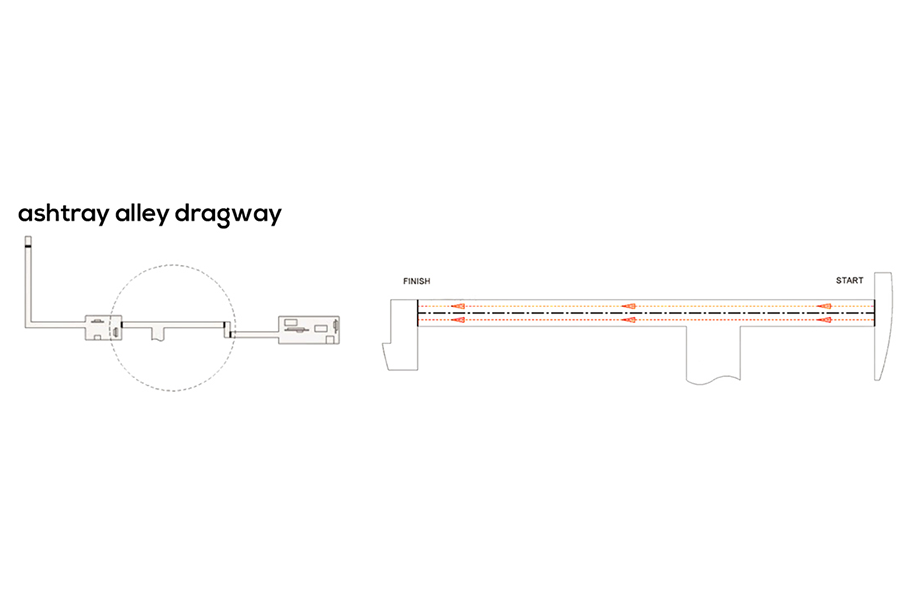

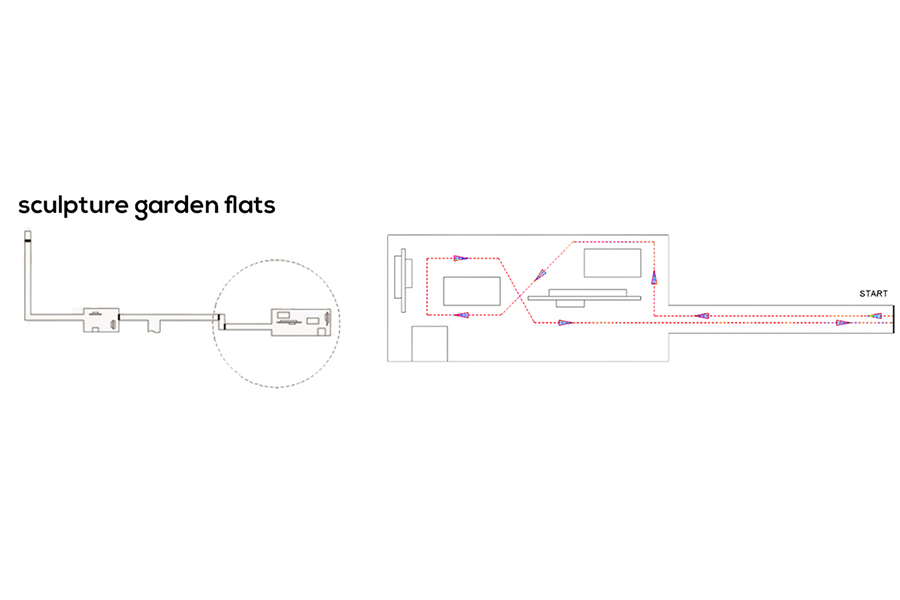

Race day consists of three events: an endurance-testing hill climb with a 90º turn, a drag race testing top-line speed, and a figure-eight testing maneuverability. Each team is given a 16-foot rubberband and two servos. Beyond this, any strategy or materials can be used to design a winning car.

“Find solutions under pressure, recover from failure, and ultimately win”

|| Solution

Andross was among the more complex vehicles showcased at the Formula E event, featuring highly-technical design elements with consideration to the aesthetics and branding of the vehicle. Fabrication required CNC machining (foam cover), laser cutting (plastic frame), 3D FDM printing (component housings), and lathing and machining (aluminum drive system). The sum of these fabrication processes created a vehicle of unparalleled functionality and aesthetics.

“Highly-technical design elements with consideration to the aesthetics and branding of the vehicle”

|| Process

Ideation & Testing

Prototyping

3D Modeling

Fabrication

Branding

Community Service

Team Andross hosted a one-day automotive design workshop with local charity CreateNow, which provides arts mentorship to underprivileged children. We accommodated over 20 children who enjoyed a half-day of sketching instruction followed by a competition to prototype a simple car propelled by a rubberband.